| |

The German Wenda

Albert Strange's Wenda design was first published in 1906 in The Sailing Boat by HC Folkard. However, it was not until it was rediscovered there in 1976 by Mike O'Brien, and subsequently redrawn for WoodenBoat magazine, that it generated interest. Amongst those captivated by it's charm was Julian Sarfert who set about employing a couple of Czech father & son shipwrights to build Wenda. The method of construction is described as a “modern, low-maintenance wood-epoxy system”.

Launched in 1999 at the Urfahrn Yacht-Club, Wenda's maiden voyage was on the Chiemsee, affectionately known as the 'Bavarian Sea', a freshwater lake in Bavaria Germany. Following her first voyage, Harald Schwarzlose wrote up an account of how Wenda came to be. A translation of this article from German by 'Pacal' is reproduced below.

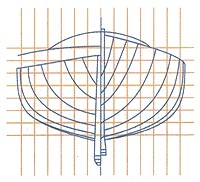

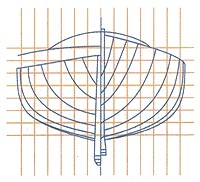

Hull Form of Wenda

The Translation Of Harald Schwarzlose's Wenda Report

A man from Berlin had a small canoe yawl built in the Czech Republic. The plan from Albert Strange is over 100 years old.

“Wenda will call attention to herself wherever she sails”, wrote the North American builder Philip C Bolger to Julian Sarfert in Berlin, who had discovered the plan of this small two-masted lugger in WoodenBoat magazine. At that time, the original lines of Wenda were just about 100 tears old, drawn by one of the most famous designers of his time, the Englishman Albert Strange. Julian Sarfert, a fan of traditional yachts, fell in love at once with the lovely canoe yawl and ordered the plans from Bolger. As usual in his time, Strange had not produced precise building drawings with all required measurements, but simply drawn the dominant lines. Everything else was left to the boat builders. So it came that Philip C. Bolger was asked to produce construction drawings, which in turn were transformed by Sarfert to the metric system. “It was a huge job”, he said at the launch of Wenda at Urfahrn harbour on the Bavarian Chiemsee lake, “but it was worth it”. He's right.

The flat, slender hull with the elegant canoe stern and the lifted bow is as beautiful today as in Strange's time. But only the achieved unison of excellent craftsmanship and classic lines transformed it into a work of art. “It was very difficult to convince the two builders of the need to produce all traditional elements of the boat exactly by the plan's specification”, says Julian Sarfert. In southern Boehmen, where he runs a production unit for ceramic building components, he met the Stanys, father and son, who had made a name for themselves building and restoring wooden yachts. They showed interest in this unusual boat, even though the construction technique was unknown to them. The hull was built as a self-supporting shell from red cedar wood strips, glued with epoxy over temporary building frames. The building jig had been assembled by Sarfert himself in the boatshop, which was nothing but a garage. No problem, for he had already built two boats himself.

But as Sarfert mounted the building frames and dry fitted the first strips, he discovered to his frustration, that they wouldn't lie fair over some segments. Where had this problem been introduced ? Was it that the old master Strange altered on purpose the hull lines to avoid unlicensed copies (quite common in those years), or did the mistakes come from the revisions done by Bolger ? In any case, Sarfert had some trouble correcting the temporary frames, so that the strips would lie fair.

The plan shows a modern midship section,

while the bow and stern resemble each other with their canoe shapes.

As the materials were not available in the Czech Republic, Sarfert bought them in Germany. There are a total of 720 m of strips in the hull. The red cedar strips, measuring 45 mm x 15 mm had one concave and one convex side. This permitted easy assembly on curved parts of the hull. Apart from the epoxy glue they are edgeglued with oak plugs each 20 cm. “I wanted to avoid internal framing for weight reasons” explained Sarfert; “Only in the area of the main mast did we install a strong laminated frame”.

Philip C. Bolger was not sure if Strange had drawn the boat originally for carvel or clinker. “Probably the original would have been carvel planked”, Bolger wrote, “because clinker was for fishermen, but a smooth skin was for gentlemen sailors!”

And so the building of Wenda progressed slowly in the Czech Republic, while the owner unnerved the builders by his quest for perfection. The roof of the flat cabin had to be completely removed by the Stanys, because they had not built it spherically, but simply arched in cross-section. Each beam for the cabin roof was then laminated with a special curvature - a time consuming job. In the end, 3200 hours had gone into the 7.55 m yawl. The beauty of the hull form and the harmony of proportions began to emerge step by step. The hull was painted creamy white, like the original boat. Below the waterline, the original would have been covered in copper, so the under water body was painted copper colored. This paint scheme does not follow exactly the waterline at the bow. Instead, it is pulled upwards, following the lifting sheerline, “as it used to be done with the coppered old boats” says Sarfert.

The deck was covered in 12 mm thick teak strips, glued over plywood without screws or plugs. This helps to eliminate leakage points. Covering boards and coaming, as well as bulwarks and rubrails, were built from noble mahogany hardwoods.

Strange had equipped the flat-bottomed long keel boat with a narrow centreboard for coastal cruising, so that Wenda can dry out without problem. The centreboard case is completely enclosed and the centreboard's shape helped to keep the case very low. This way, it hardly encroaches on the small cabin, which holds only two berths. The L-shaped extension to raise and lower the centreboard comes up through the deck, from where it is controlled by a simple tackle. The long keel, which carries to the “historic” rudder, is composed of a zinc-covered iron tub, filled with lead, and fixed to the oak keel, taken from the bavarian forests. “The ballast component of the boat is nearly 50%”, says Sarfert, “This illustrates much importance was given to a stiff hull in those days”. In fact, I can stand to one side of the deck without leaning her noticeably. Considering the light strip built hull, the boat has now even more sail carrying capacity than the original carvel construction.

As we make ourselves comfortable on the seats in the cockpit, I can only just see over the coaming and cabin roof, so deep are the seats. This gives the impression of sailing a much bigger boat. “Like on the original, we built the cockpit deep, but not self-draining”, says Sarfert. “Self-draining was not necessary, since the cockpit is separated from the interior. If she should ever take on water, I can get it back out easily with the powerful electric pump”. Even with the cockpit full of water, the boat's floatation stability is not endangered.

The love of details is visible everywhere. The cabin door, offset to starboard, was built of solid mahogany wood, with the cross members for the window glued onto the safety glass (taken from a truck at the dump). The bulls eye for the cabin roof was also cut from this special glass, with the waterproofing provided by the screwed and hand polished stainless steel frame.

Owner Julian Sarfert gets a lot of pleasure from the ship.

The deck planks are nibbed into the covering board in the traditional way.

The teak strips are fitted traditionally to the Schandeck

Mast and spars for the historic yawl rig were built from spruce. The main mast goes through the deck and is keel stepped. It can be raised or lowered by one man. The mainsail is lug rigged (which means that the lug yard is attatched to the mast without a gaff saddle), but the small mizzen is gaff rigged with a gaff jaw. “This appears confusing at first sight”, admits Sarfert, “but on the water it is very easy to manipulate, and the sail area is well distributed”. In a gale, the yawl can be sailed without the main, only under headsail and mizzen. The only concession to modernity is the furler for the headsail, “to control it without going onto the foredeck”, and a flat lifeline, “because we sail with small children”.

Wenda convinces thanks to her details, such as the anchor box in front of the mast.

The centreboard is controlled with a tackle, the ballast sits in the long keel.

The cockpit (not self draining) is deep, the coaming high.

The black boxes control the electric engines.

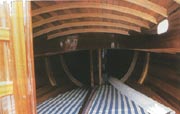

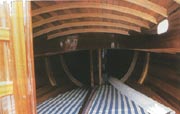

The homely interior without any lining shows

the strip build method, with little framing.

The sails were also kept as closely to the original as possible. Sailmaker Hubert Raudaschl of Austria had to sew them from yellowish cloth with narrow strips, “since the sails from the turn of the century could only be built this way” knows Sarfert. For motoring, two electric engines were chosen, bolted both sides of the keel in front of the rudder. The hull is penetrated only by the cables leading to the regulators, connected to four Gel-batteries. They were included in the stability calculations, and should give 25 hours of service. In a calm, two electric engines give almost 6 knots of speed.

I was convinced of the power of the engines on launching day at Chiemsee. Julian Sarfert opened the cockpit locker and twisted the controlling knobs. There was a pleasantly quiet humm under the cockpit floor as we pull away from the jetty onto the sunlight-flooded lake. Out in the open, the owner turned on maximum power, and I could only marvel at the pushing force generated. The lean boat plowed along at between 5 and 6 knots. “This is sufficient for heading into wind and waves”, says the owner, and I believe him. However, Sarfert wishes to retrofit an electric inboard with a shaft train and folding propeller, because the two engines besides the keel do slow the boat considerably when sailing.

A light breeze called for setting all sails, which is done in an uncomplicated manner from the cockpit. Wenda picked up speed quickly and swept across the quiet surface. It really is a special experience, to sit on a historic boat that floats like a seagull under the slight pressure of its traditional rig. Tacks and gibes go quickly, the yawl rig gaves us no problems. Modern boats approached, their crews wave and shout appreciative words. How did Philip C. Bolger write ? “Wherever Wenda appears, she will call attention !” And that's how it is.

Wenda Statistics

Built : 1999 by The Stanys (Father and Son) in Czech Republic

LOA : 24' 9"

LWL : 19' 3"

Beam : 6' 5"

Draught : 2' 6"

Displacement : 1.52 tons

Design : N° 45, Wenda

Julian Sarfert

Wenda Custodians & Home Ports

Julian Sarfert (1999-2016...) Chiemsee, Germany

Page last updated : April 2017

| |